Features:

10 x Bullet Weld on Lift off Hinge

Dimensions: 60mm-200mm

Material: Steel Weld on

Fitting: Greaseable

Pin: Steel Pin

Size Option: A. 10mm x 60mm, B. 13mm x 80mm, C. 16mm x 100mm, D. 20mm x 150mm, E. 23mm x 200mm

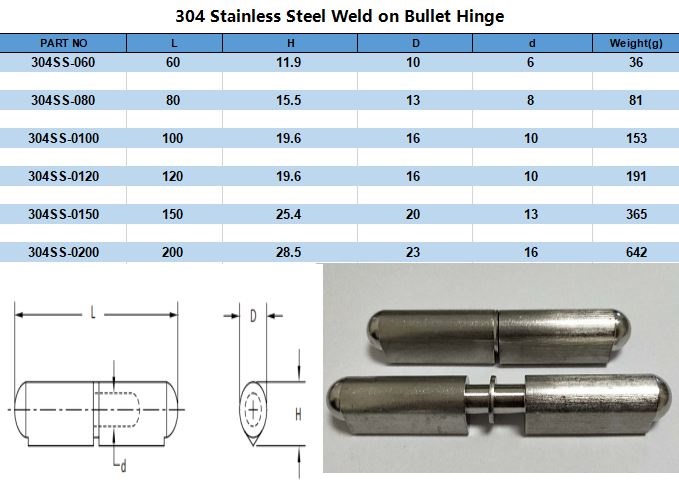

| Steel-Ungrease | L(mm) | H(mm) | D(mm) | d(mm) | Capacity | Weight | |

|---|---|---|---|---|---|---|---|

| 10mm x 60mm | 60 | 11.9 | 10 | 6 | 59kg | 36g | Check Price |

| 13mm x 80mm | 80 | 15.5 | 13 | 8 | 124kg | 82g | Check Price |

| 16mm x 100mm | 100 | 19.6 | 16 | 10 | 211kg | 153g | Check Price |

| 16mm x 120mm | 120 | 19.6 | 16 | 10 | 246kg | 191g | Check Price |

| 23mm x 200mm | 200 | 28.5 | 23 | 16 | 650kg | 642g | Check Price |

|  |

||||||

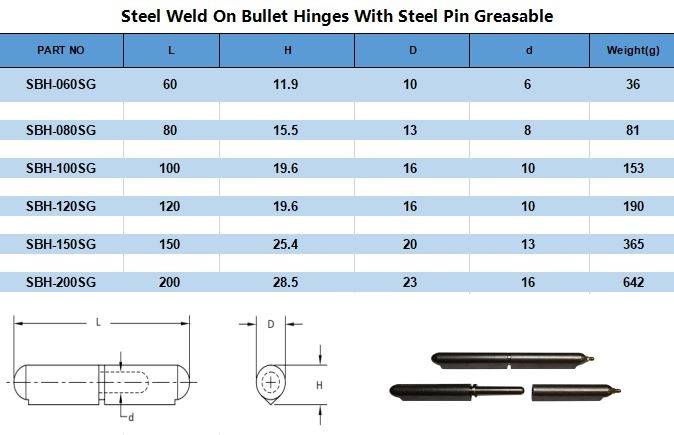

| Steel-Grease | L(mm) | H(mm) | D(mm) | d(mm) | Capacity | Weight | |

| 10mm x 60mm | 60 | 11.9 | 10 | 6 | 59kg | 36g | Check Price |

| 13mm x 80mm | 80 | 15.5 | 13 | 8 | 124kg | 81g | Check Price |

| 16mm x 100mm | 100 | 19.6 | 16 | 10 | 211kg | 153g | Check Price |

| 16mm x 120mm | 120 | 19.6 | 16 | 10 | 246kg | 190g | Check Price |

| 23mm x 200mm | 200 | 28.5 | 23 | 16 | 650kg | 642g | Check Price |

|  |

||||||

| Steel-Ungrease-Brass Pin | L(mm) | H(mm) | D(mm) | d(mm) | Capacity | Weight | |

| 13mm x 80mm | 80 | 15.5 | 13 | 8 | 60kg | 81g | Check Price |

| 16mm x 100mm | 100 | 19.6 | 16 | 10 | 125kg | 150g | Check Price |

|  |

||||||

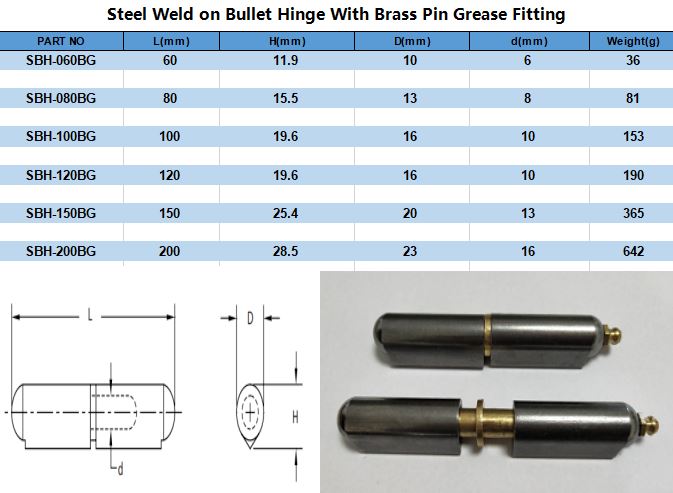

| Steel-Grease-Brass Pin | L(mm) | H(mm) | D(mm) | d(mm) | Capacity | Weight | |

| 13mm x 80mm | 80 | 15.5 | 13 | 8 | 60kg | 81g | Check Price |

| 16mm x 100mm | 100 | 19.6 | 16 | 10 | 105kg | 153g | Check Price |

|  |

||||||

| Stainless-Ungrease | L(mm) | H(mm) | D(mm) | d(mm) | Capacity | Weight | |

| 10mm x 60mm | 60 | 11.9 | 10 | 6 | 59kg | 36g | Check Price |

| 13mm x 80mm | 80 | 15.5 | 13 | 8 | 124kg | 81g | Check Price |

| 16mm x 100mm | 100 | 19.6 | 16 | 10 | 211kg | 153g | Check Price |

| 16mm x 120mm | 120 | 19.6 | 16 | 10 | 246kg | 191g | Check Price |

| 20mm x 150mm | 150 | 25.4 | 20 | 13 | 381kg | 365g | Check Price |

|  |

||||||

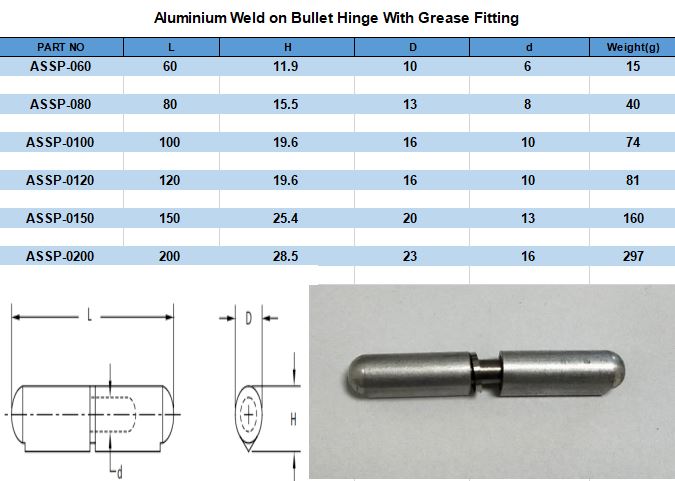

| Aluminium-Grease | L(mm) | H(mm) | D(mm) | d(mm) | Capacity | Weight | |

| 13mm x 80mm | 80 | 15.5 | 13 | 8 | 124kg | 40g | Check Price |

| 16mm x 100mm | 100 | 19.6 | 16 | 10 | 211kg | 74g | Check Price |

|  |

||||||

If you want your bullet weld on hinge to be strong and durable yet light in weight, choose aluminium bullet hinges. Just like the hinges mentioned above, their corrosion resistance is excellent for the harsh environments outside. Aluminium bullet hinge offers secure connection and a smooth, clean, and sleek appearance. You can use this bullet hinge type on safes, doors, gates, safety containers, toolboxes, metal cabinets, cab enclosures and several other things.

What Is Bullet Weld on Lift off Hinges?

Also referred to as weld on hinges, lift off hinges, and barrel hinges, bullet hinges provide users an attractive yet compact and strong method to attach metal doors with metal frames. These hinges come in quite handy for enclosures, gates, tool cabinets, agricultural purposes, electrical purposes, and are perfect for several other industrial as well as residential applications.

Our Bullet weld on hinges is available in steel, stainless and with brass, steel, stainless steel pins, with grease fittings as well as without grease fittings. Furthermore, they are available in various sizes from 60mm t0 150mm to make sure that the user can fit them according to their requirements and convenience.

What Is Bullet Lift off Hinges Ideal for?

Barrel or bullet weld on hinges are an excellent solution for people who have to deal with limited welding space on their frames or doors. Our Weld on hinge, provide a strong, compact, and attractive method of attaching metal doors to metal frames for electrical, agricultural, security, safe, tool cabinets, gate, enclosure, and many other industrial applications. Suitable for tight spaces. Can be welded on doors, tailgates, security gates, garden gates, boats, canopies, truck bodies, gates, toolboxes and metal cabinets.

They are used in a wide range of industries from shipping to construction, electronics and automotive. Bullet hinges are ideal for narrow frames where there isn’t much room to use another type of hinge.

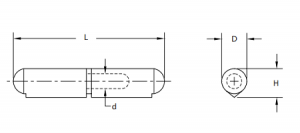

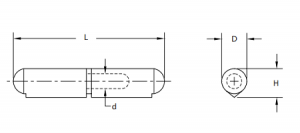

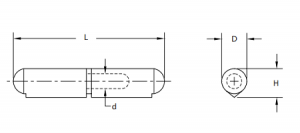

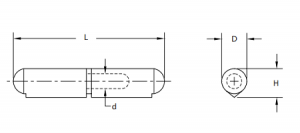

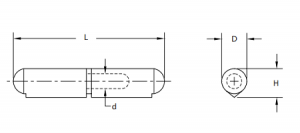

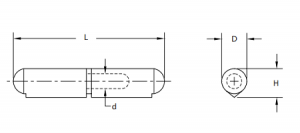

What Does a Bullet Lift off Hinge Consist of?

Weld on bullet hinges consist of three main parts. These parts are the leaf side (also known as female), the pin side (also known as male), and a brush that stands between two halves. Bullet hinges that are made out of steel come along with brass brushing. Aluminium bullet hinges, and stainless-steel bullet hinges on the other hand are mostly provided with grease fittings. In most cases, the grease fittings are optional.

The bullet weld on hinge stock that we have at our disposal consists of different sizes that range from 60mm to 150mm. These sizes perfectly correspond with hinge lengths and will not cause any issue when you weld them. You can use barrel or bullet hinges for non-removable as well as lift off applications for doors.

In lift off applications, both the hinges are aligned with pins that point at the same direction. In non-removable applications on the other hand the hinges fall in line with the pins which point towards each other. So, whether you need two pieces or thousands of them, the vast inventory that we have will be more than sufficient for your bullet hinge needs.

Bullet Hinges Offer a Functional Solution

These hinges also come in handy for cabs, boats, trailers, and truck bodies, traffic light controls, etc. Security gates, cab enclosures, toolboxes, fishing equipment, and barbecue pits. No matter which kind of bullet hinge material you prefer, it is capable of withstanding substantial loads. On top of that, these hinges are also perfect for narrow frames.

If you are looking for a perfect alternative to traditional hinge types a heavy-duty bullet hinge will prove to be a perfect choice.

What Makes Bullet Weld on Hinges So Functional

Bullet hinges are particularly created as two halves that users can directly weld them separately on their desired surfaces. As mentioned earlier, these halves are known as the female and male barrels. It is a major reason why bullet hinges are also known as barrel or weld on hinges. The barrel that consists of the pin is the male barrel while the barrel that doesn’t have any pin is known as the female barrel. Female barrels are weld on surfaces like doors. Male barrels on the other hand are weld on structural areas like door frames.

Since majority of the doors that utilize bullet hinges tend to be lift-off doors, the barrel without the pin must go on top. The reason behind it is that most lift off doors usually drop, this means that it is necessary for bottom barrels to have excellent load bearing qualities. A major advantage that lift-off doors offer to the user is that you can lift them off the hinges whenever you want. There is no need to unscrew each hinge.

The Best Bullet Weld on Hinge Materials

Although we have discussed several materials that bullet hinges are available in, mentioned below are the best bullet hinge materials out there:

Steel Weld on Hinges

Aluminium Hinges

Most people prefer using these hinges because of how robust they are and how long they last. Plus, they do no accumulate too much dirt in comparison to other hinge types. Therefore, choosing any of these bullet hinge materials will add a clean appearance wherever you plan to

install them.

Stainless Steel Hinges

We have excellent stainless steel bullet hinges in our inventory. These pins offer extra durability, strength, and resistance to corrosion. Medical, marine, food service, and several other outdoor markets can benefit from stainless steel bullet hinges. They offer a secure connection and provide a clean and smooth appearance.

Aluminium Hinges

If you want your bullet weld on hinge to be strong and durable yet light in weight, choose aluminium bullet hinges. Just like the hinges mentioned above, their corrosion resistance is excellent for the harsh environments outside. Aluminium bullet hinge offers secure connection and a smooth, clean, and sleek appearance. You can use this bullet hinge type on safes, doors, gates, safety containers, toolboxes, metal cabinets, cab enclosures and several other things.

Reviews

There are no reviews yet.