HANDHELD Packing Machine Pneumatic Strapping tool for 1/2″-3/4″ PP &PET

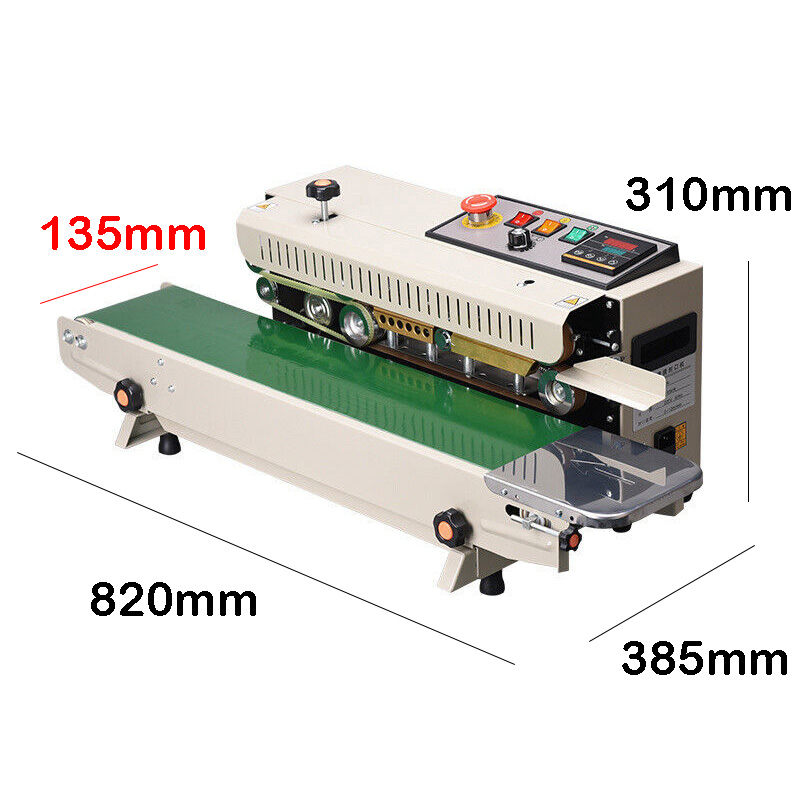

This tool is a kind of fusion packaging machine. The lapped thermoplastic packaging belt is fused by the heat produced by friction motion. Hence, it is called “friction fusion”. Principle is to use the binding tape winding product or package, then tighten and ends by heating molten or use the material such as bag buckles connection machine. It is widely used for paper, aluminium, wood, wooden packaging, chemical fiber, cotton, tobacco, chemicals, foodstuff and daily merchandise, metal products industries. It adopts PET tape to finish a strap in a high speed once. This PET tape is high-tension, environmental-protection and no-pollution and can be used to replace steel tape.

Principle of friction instruction:

The compressed air will push the piston within air cylinder. The upper part of piston and vibrating bar is connected with the rocking pin, so the vibrating bar will press the lapped part of packaging belt when moving down. There is an elliptic hole at the centre of vibrating bar. This hole is connected with the eccentric shaft of pneumatic motor. The pneumatic motor rotates at a high speed (10000rpm), so the vibrating bar conducts reciprocal motion quickly. The lower part of packaging belt is fixed by the peg teeth of fusion toothed plate, and its upper part is driven by the peg teeth of vibrator for strenuous friction. Hence, the lapped part of packaging belt is fused by the heat produced by friction. When the vibration timer reaches the set time, vibration stops, and fusion completes. Both upper and lower parts of the packaging belt are stuck while extruding.

The required scope of air pressure:

(5.0-7.0bar)

Installation of gas source

Filter, pressure regulating valve and lubricator assembly shall be close to the pneumatic tool. The min. inner diameter of air hose is 6.0mm. Both ends of air supply pipe should be equipped with quick unions.

Moisture filtration:

A drain valve must be mounted at the bottom of the air supply circuit’s bypass to drain once every day. Lubrication: Pneumatic motor should be lubricated properly, and the lubricator should be full and well regulated.

Specifications

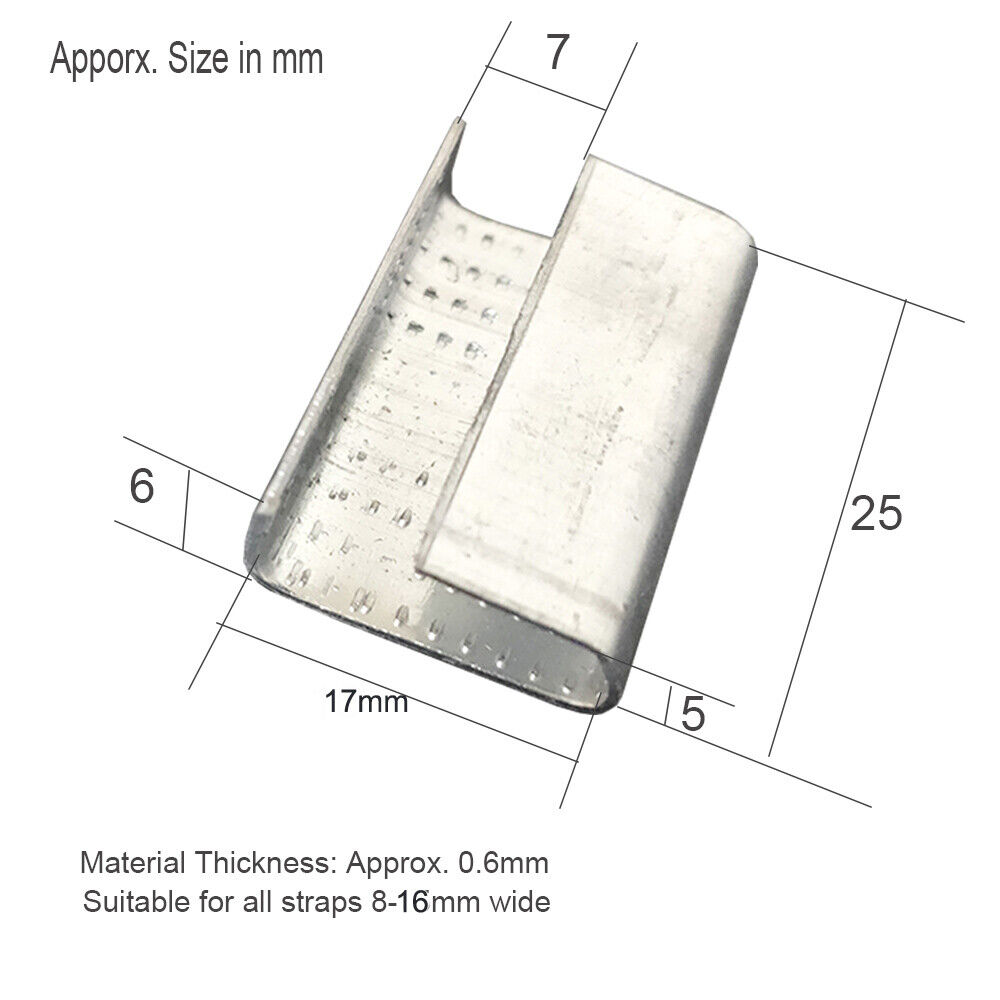

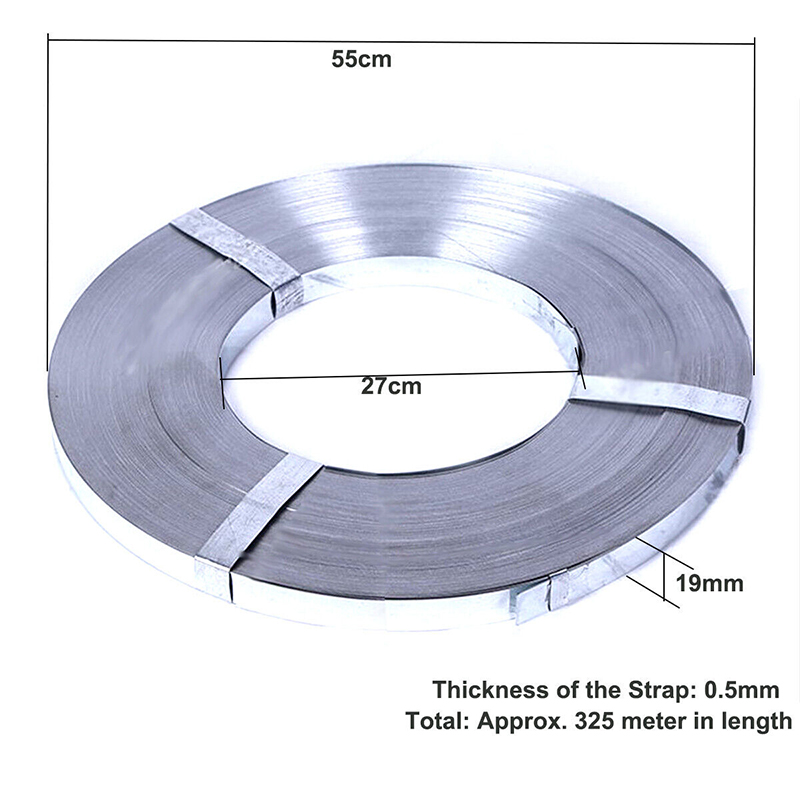

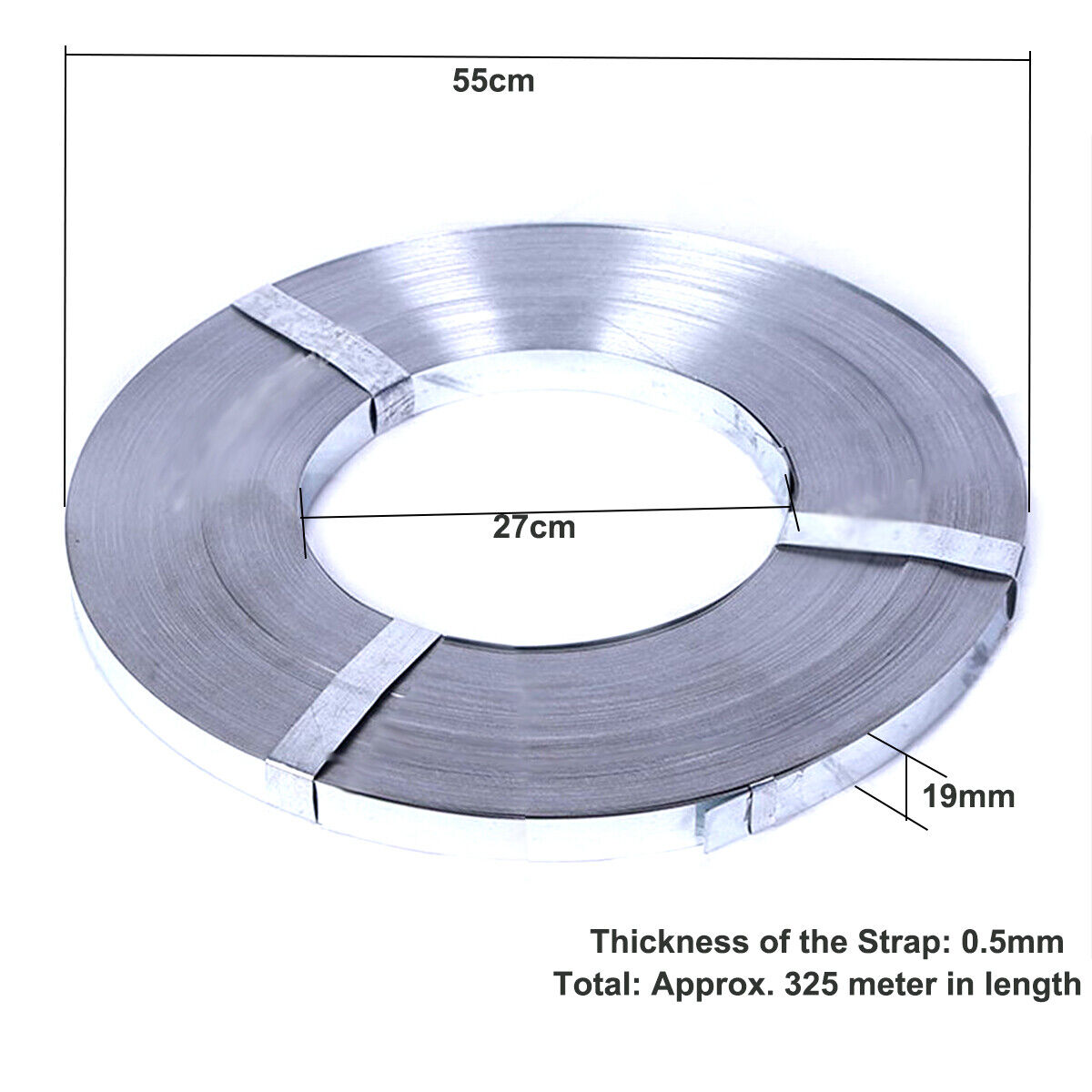

Drived: By Air Pump Strapping Material: Polyester Applications: PET Strap, PP Band Function: Tensioning, Sealing, Cutting Air Pressure: 0.5-0.8Mpa Max Strap Tension: 3500N Model: A19/ A 25 Strapping Width: 13mm(1/2”)-19mm(3/4”)/ 19mm(3/4″)-25mm(1″) Strapping Thickness: 0.5(0.0196”)-1.5mm(0.06”) Suitable band: PP & (PET) strapping Adjust Range Welding Time: 2-5s The form of sealing: Frictional heat welding Lubricant Permitted: 51# Tool weight: 3.8kg Size: 280*160*180mm

Reviews

There are no reviews yet.